Some Known Details About Bayside Laser

Wiki Article

The 10-Second Trick For Bayside Laser

Table of ContentsAll about Bayside LaserThe Best Strategy To Use For Bayside LaserThe Definitive Guide to Bayside LaserIndicators on Bayside Laser You Need To KnowAll About Bayside LaserNot known Details About Bayside Laser

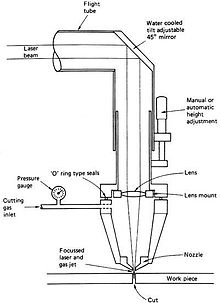

Traveling optic devices need to use some method to consider the altering beam size from the near area (near the resonator) reducing to the far field (far from the resonator) cutting. Typical techniques for regulating this consist of collimation, flexible optics, or using a consistent light beam size axis.

The power consumption and performance of any type of specific laser will vary depending upon outcome power and also operating specifications. This will certainly depend on the kind of laser and also how well the laser is matched to the work at hand. The quantity of laser cutting power needed, referred to as warmth input, for a certain job depends upon the product type, thickness, process (reactive/inert) made use of, as well as desired reducing price.

Bayside Laser Things To Know Before You Buy

The individual can conveniently control the cut's depth by changing the laser beam's power and focus (https://pxhere.com/en/photographer-me/4046366). Laser cutting is typical in steel, timber, plastics as well as fabrics.Whether you're seeking a brand-new or updating your procedures, laser cutting has broad applications, specifically in production. That stated, here are four advantages of laser cutting: Laser cutting is one of one of the most advanced, specific as well as exact techniques for reducing products. It can provide a degree of detail and also precision that hand tools can never ever get to.

All about Bayside Laser

The potential for laser cutting seems almost infinite as it offers companies top quality typical results in a fraction of the time. Laser-cutting innovation is flexible and compatible with numerous materials, varying from wood as well as leather to even more difficult-to-cut metals. For these harder-to-cut materials, laser cutters develop best precision cuts that are not available with traditional cutting devices.Laser-cutting machines are as uncomplicated as many equipment goes. Still, right here are four pointers to aid get the most out of your process: With laser cutting, selecting the suitable material for the work is critical. Relying on the intended application, different products may be more suitable than others depending upon variables such as durability and also security.

Fascination About Bayside Laser

Obviously, laser cutting is a whole lot faster than the standard approach of cutting steel, but is it faster than various other modern methods? Yes, it is. Laser cutting beats thermal reducing techniques such as plasma or flame in speed when cutting steel of up to 10mm thick. That being claimed, if you desire the fastest outcomes you need to deal with the most effective metal laser reducing equipments such as those made use of by GF Laser who make use of the latest Trumpf Laser makers (laser cutting acrylic).For those that need to reduce lots of different shapes, laser cutting is most definitely the most attractive metal reducing alternative. With this approach of cutting metal, you do not need to alter devices to make different cuts as the specific very same arrangement will certainly lug out numerous reducing work as long as the density stays the same.

Throughout the laser cutting procedure, the beam utilized does not in fact require to touch the product that is being reduced, causing much less risk of damages. This indicates that you will certainly not require to incur expensive fixings or postponed conclusion times as you could with other approaches of cutting steel - laser cutting brisbane.

Bayside Laser - The Facts

Laser reducing requires much less power than various other techniques, utilizing usually 10k, W of power contrasted to 50k, W for other cutting procedures. Of program, the safety and security of your workers is constantly at the center of your mind as well as laser reducing supplies among the best resource means of cutting metal.That precise point creates a very high intensity that can cut via the product. Compared to conventional reducing techniques, laser reducing deals several benefits.

Unlike numerous making machines, laser cutters commonly do not require you to change out various devices for whatever cut you desire. Laser cuttings use severe accuracy compared to various other typical cutting techniques.

All About Bayside Laser

Depending upon how a laser cutter is set up, you're frequently going to observe possibly a tiny burr on a component. Normally, it's not required to get rid of the burr, but it depends upon the material, its thickness and also other factors. Oh yes, this is one of the best parts of making use of a laser cutter; versatility.

No work is also complicated for the laser cutter. A very slim area of product is conveniently navigated by the high-powered laser and also is really seldom distorted or distorted. Tasks are not simply restricted to sheet steel with a laser cutter. Lasers have the capacity to reduce stainless-steel, light weight aluminum, copper, and brass.

Report this wiki page